Beyond Traditional CMMS Software: The New Standard for Maintenance Execution

CMMS software was revolutionary 20 years ago. In 2026 it's table stakes. The real crisis is that 92% of maintenance work happens in execution chaos CMMS can't handle. Need a live operational layer above your CMMS? Discover Maintenance Execution Intelligence with Equipt.ai

- Technology Trends

- Digitalization and Asset Intelligence

When CMMS software first hit the market, it was revolutionary. Paper logbooks and Excel spreadsheets gave way to digital work orders, preventive maintenance schedules, and searchable asset histories. Maintenance managers finally had visibility into backlogs, PM compliance, and failure patterns. Shops and plants everywhere breathed a sigh of relief.

That was 20 years ago.

The Silent Execution Crisis in Asset-Heavy Operations

Fast forward to 2026. CMMS software has become table stakes, not competitive advantage. Every competitor has it. Every RFP demands it. But operations leaders across energy, equipment rental, industrial services, and transportation are quietly frustrated.

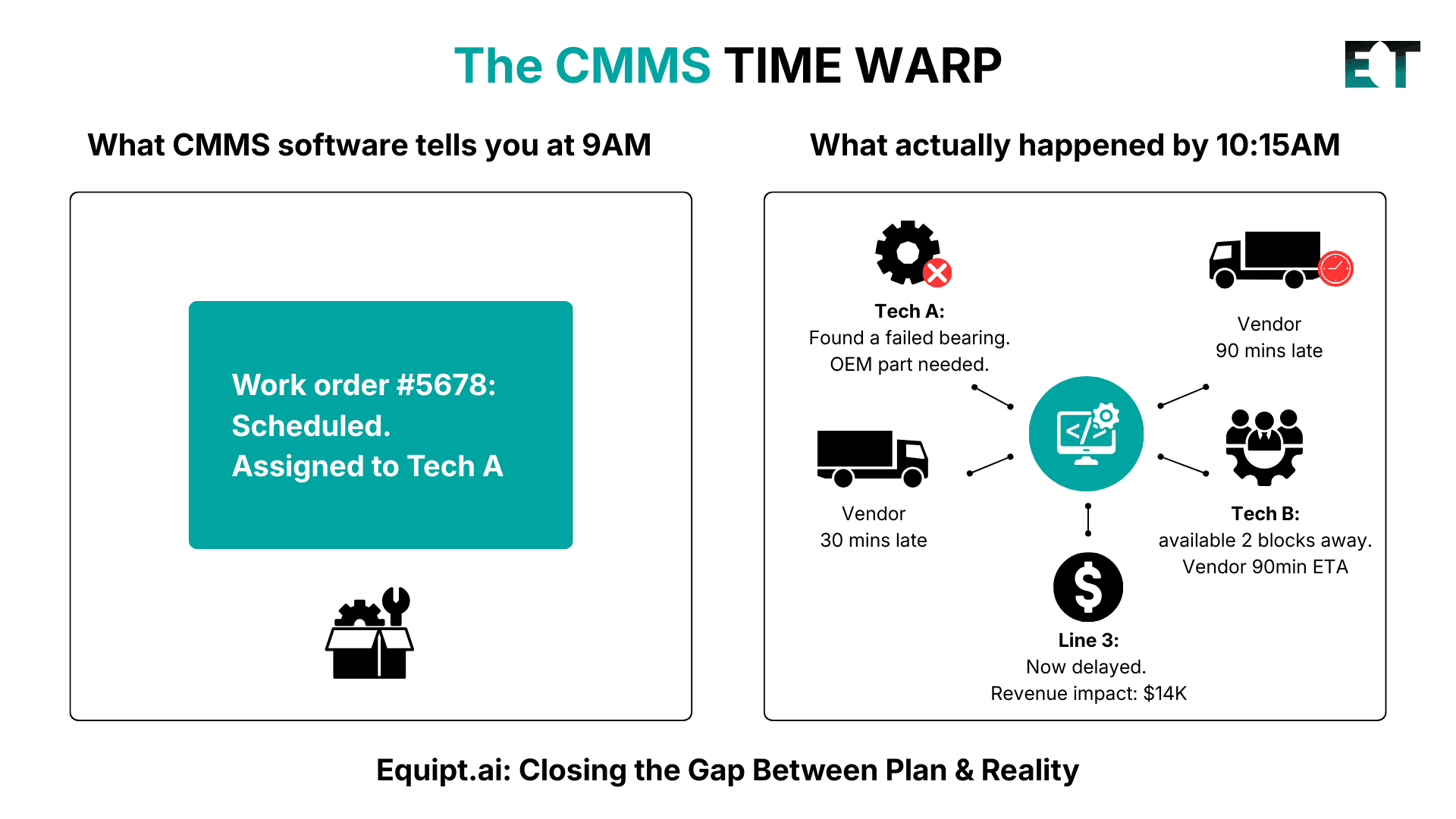

The problem isn't missing features. It's missing reality.

Traditional CMMS software captures planned work beautifully. It falls apart when reality intervenes, which is daily in asset-heavy operations.

5 Execution Gaps That Compound Hourly

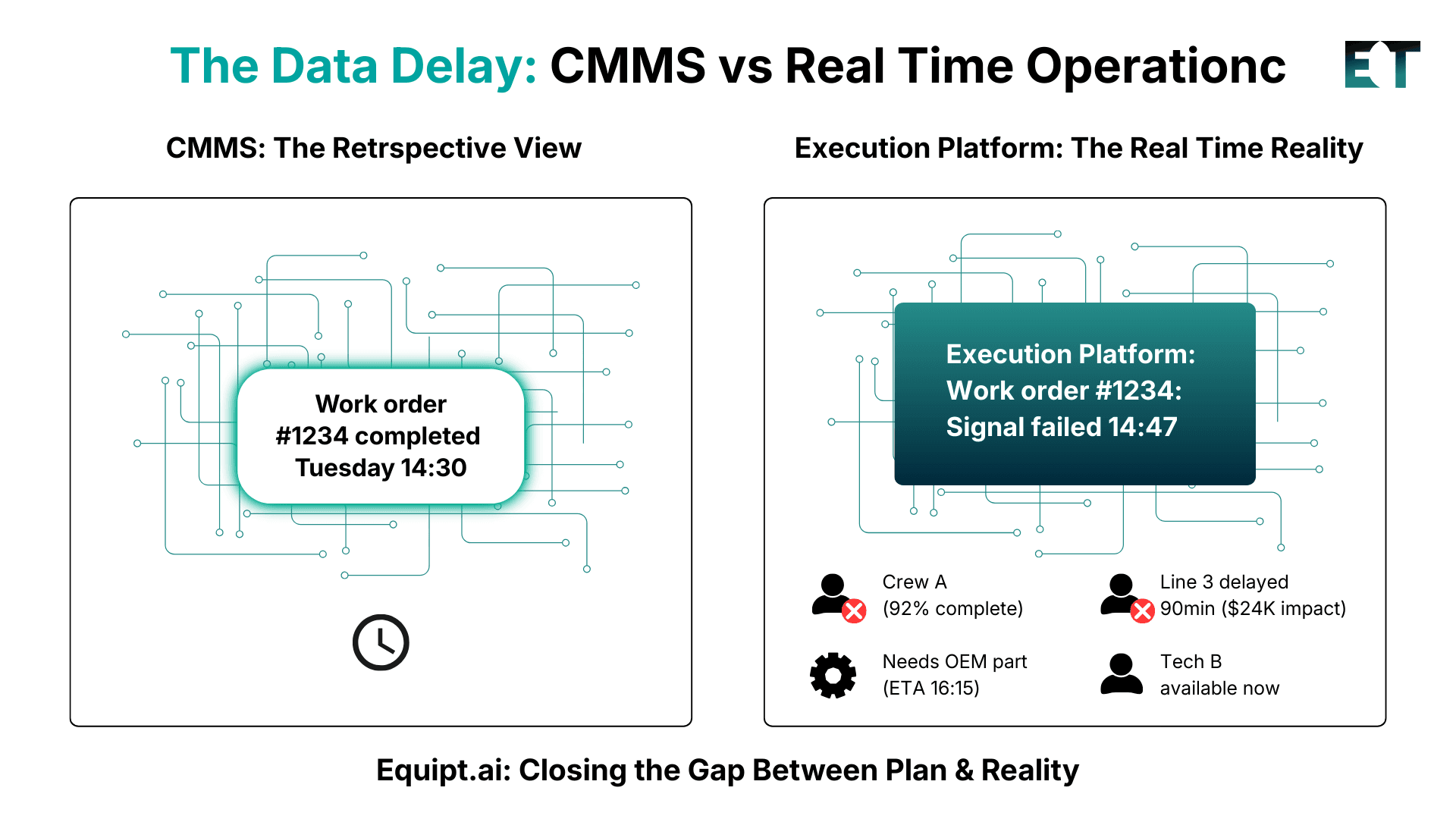

Gap 1: Status Lag Work orders show "In Progress" for jobs completed 4 hours ago. Planners schedule around ghost work. Crews get dispatched to finished jobs.

Gap 2: Field Silence Technicians capture zero condition data during execution. Asset reality (vibration, leaks, error codes) stays in their heads until the end-of-shift paper form, if it gets filled out.

Gap 3: Siloed Visibility

Planners see CMMS work orders

Supervisors see technician WhatsApp updates

Executives see delayed ERP reports

Nobody sees current operational reality

Gap 4: Manual Coordination Parts availability? Phone calls to 3 depots. Vendor ETA? Text chain with 17 messages. Crew rescheduling? Spreadsheet update + emails.

Gap 5: After-The-Fact Insights Analytics show "PM compliance dropped 8% last month." No one knows which 12 jobs caused it or why.

These aren't edge cases. This is 92% of maintenance work in asset-heavy industries. (Learn more: CMMS vs EAM vs FSM)

Why CMMS Software Can't Evolve

CMMS was designed as a record-keeper, not a live operations platform:

Event-Driven, Not Continuous: Updates happen when users log in/out

Work Order Centric: Can't handle ad-hoc coordination across jobs

Desktop-First: Field teams need mobile during execution

Planner Perspective: Doesn't reflect technician reality

Static Hierarchies: Can't adapt to vendor delays, part shortages, crew changes

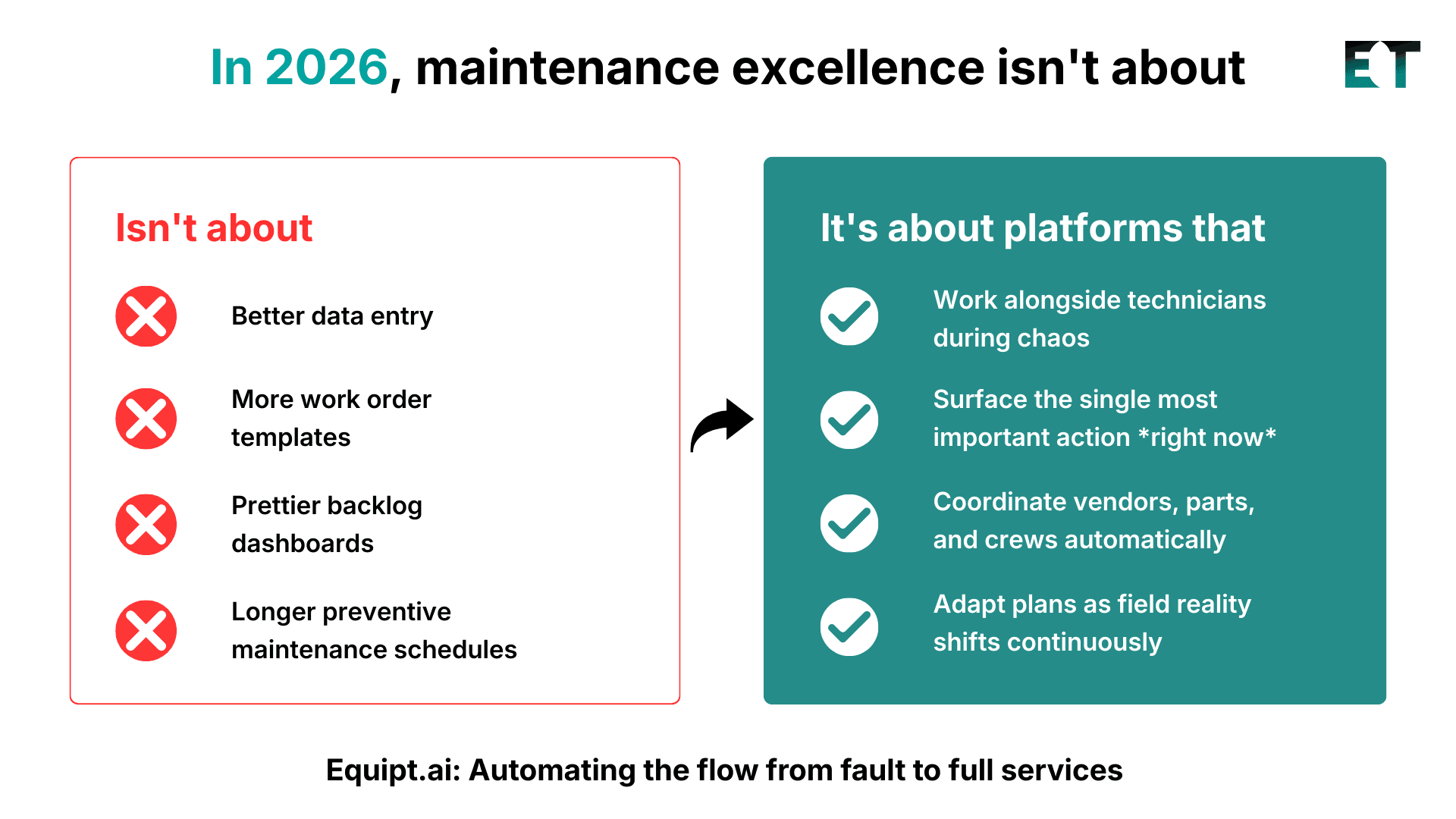

The industry tried layering AI analytics on top. It made dashboards prettier but didn't solve execution friction.

The New Standard: Maintenance Execution Intelligence

Modern platforms don't replace CMMS software. They become the live operational layer that sits above it.

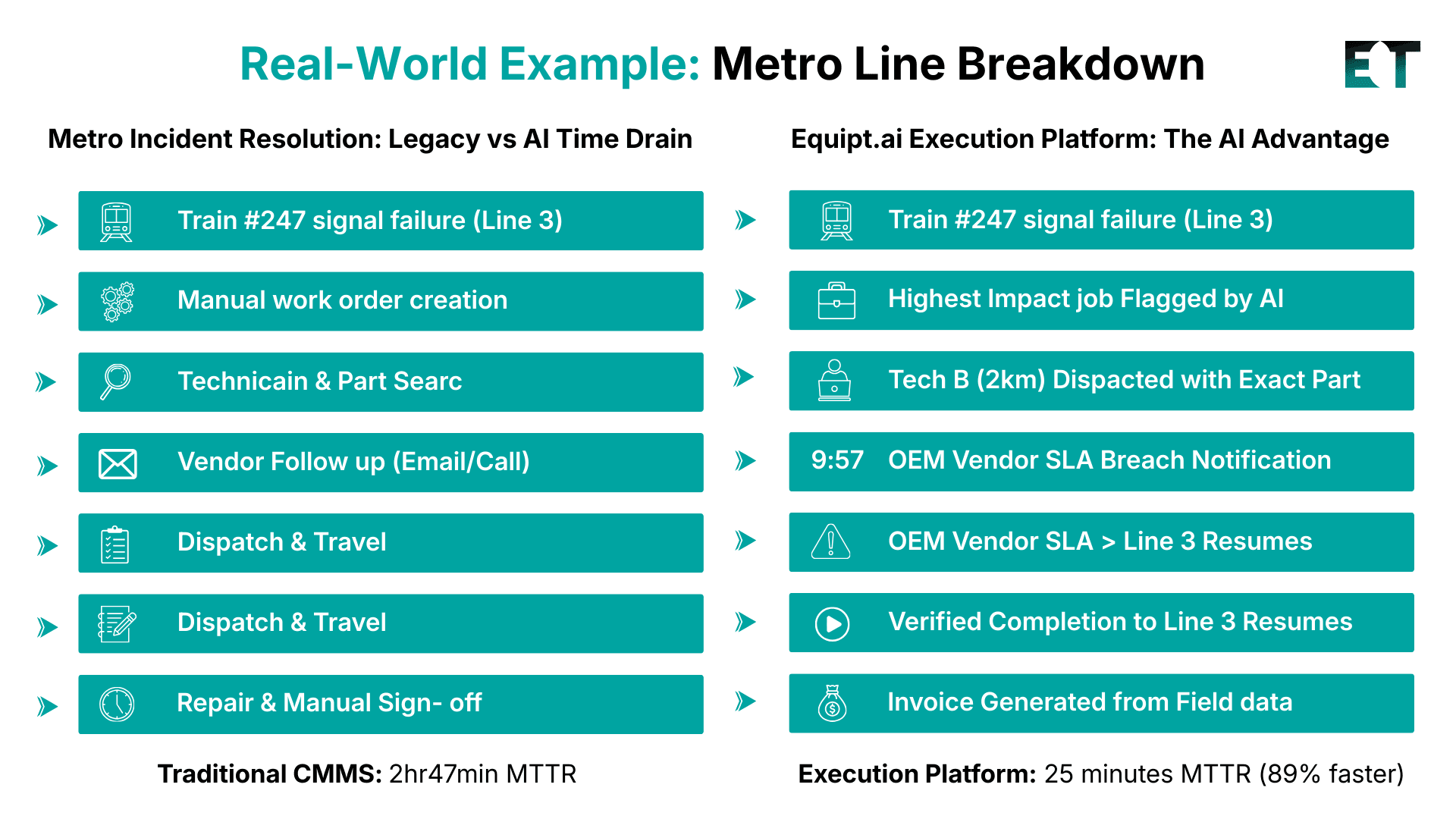

Real-World Example: Metro Line Breakdown

7 Business Outcomes That Transform Operations

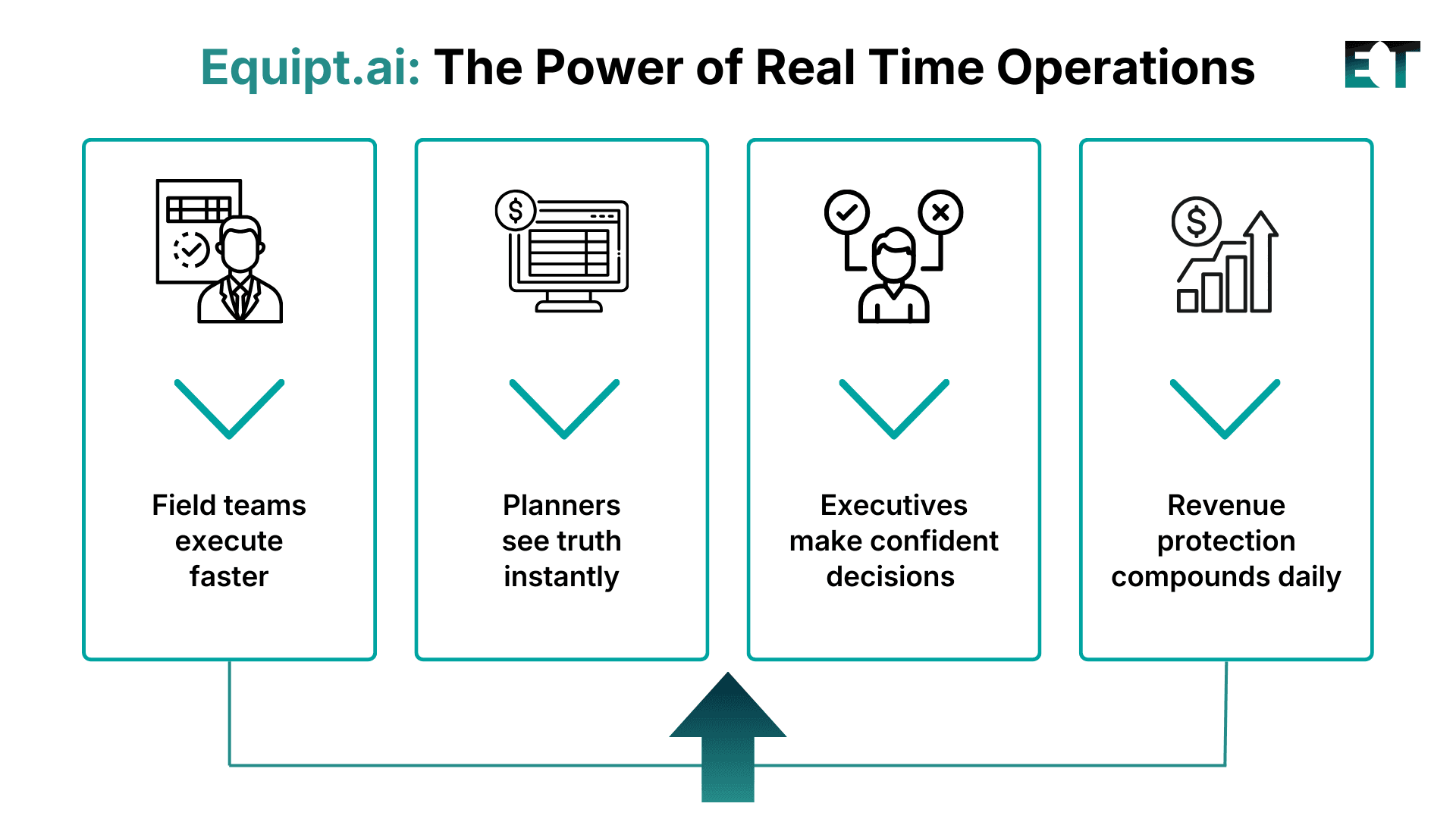

Immediate Operations Wins:

MTTR drops - Issues surface + resolve faster

Technician utilization up - Right skills, right place, right time

Vendor disputes cut - Digital proof eliminates "he said/she said"

PM compliance rises - Reality-based scheduling

Strategic Leadership Gains:

Network-wide bottleneck visibility - See exactly what's constraining throughout

Confident fleet decisions - Know utilization before buy/sell/lease (Compare oil and gas asset management software)

30% faster cash conversion - Field completion → verified billing (no re-entry)

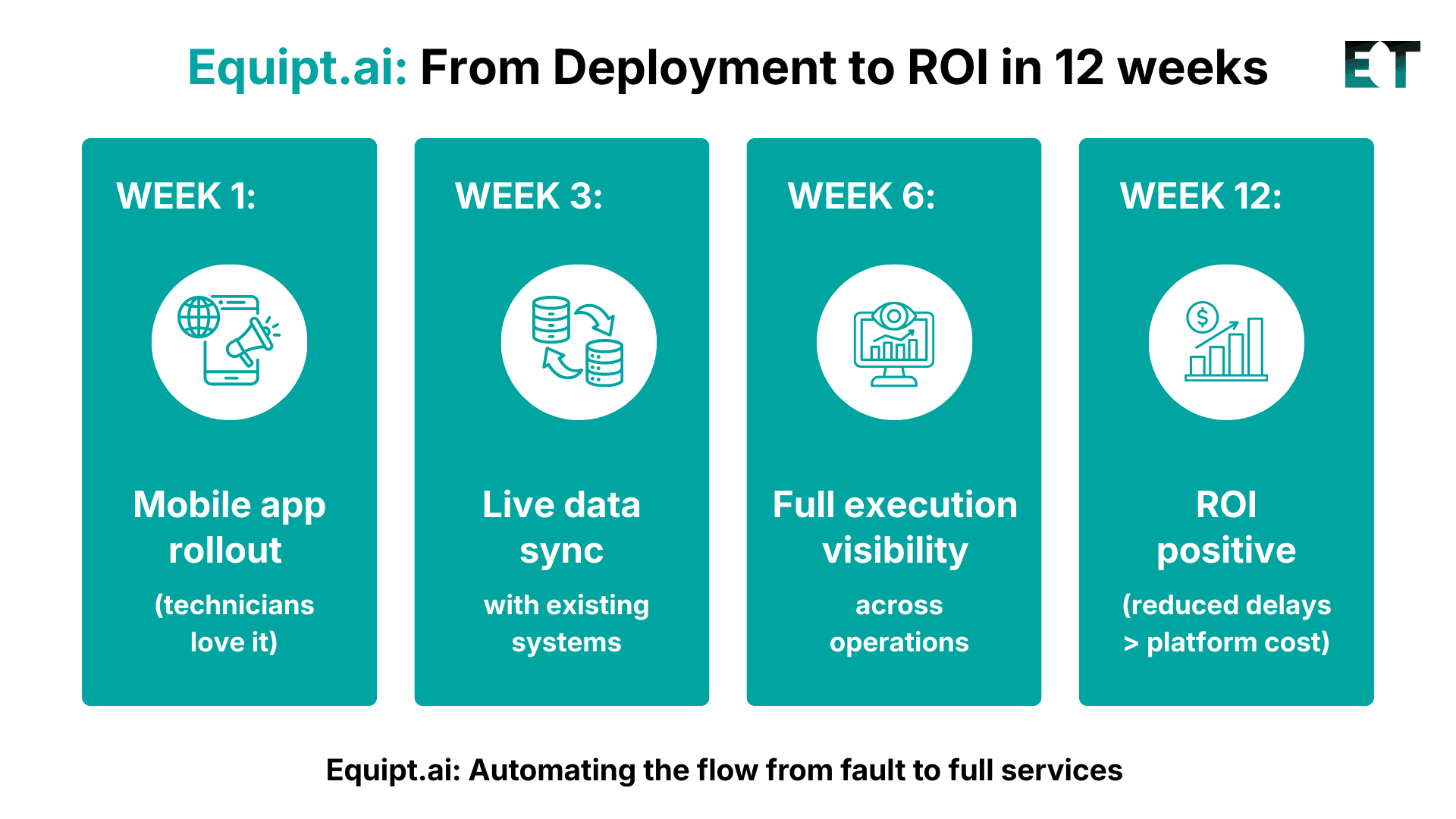

The Implementation Reality Check

Good news: Execution platforms layer on top of existing CMMS software, ERP, and SCADA.

No rip-and-replace. Your CMMS handles compliance records. The execution layer handles live operations.

The Competitive Edge: Execution as First-Class Problem

CMMS software remains essential for audit trails and regulatory reporting. But the operations that pull ahead treat maintenance execution as their core competitive advantage.

Why Equipt.ai Was Built for This Moment

Energy, rental, and industrial service companies face unique execution complexity:

Rolling assets across yards, depots, customer sites

Multi-vendor ecosystems with real-time SLA pressure

Revenue-critical service windows (trains, rentals, field jobs)

Regulatory + safety compliance across jurisdictions

Equipt.ai delivers preventive, predictive, and proactive maintenance through a single execution platform that closes the gap between planning and reality.

See the execution gap close live. Book a demo.