AI Field Service 2026: Intelligent Dispatch + Route Optimization vs Basic FSM

The gap between legacy record-keeping and predictive execution has become a chasm. Discover how AI-driven intelligent dispatch and route optimization are redefining asset uptime and protecting margins in the high-stakes industrial sectors of 2026.

- Technology Trends

- Digitalization and Asset Intelligence

The landscape of industrial operations is undergoing a fundamental shift. As we enter 2026, the gap between companies using traditional tools and those leveraging artificial intelligence has become a chasm. In the high-stakes sectors of energy, mining, and heavy rentals, the ability to move fast is no longer just an advantage; it is a requirement for survival.

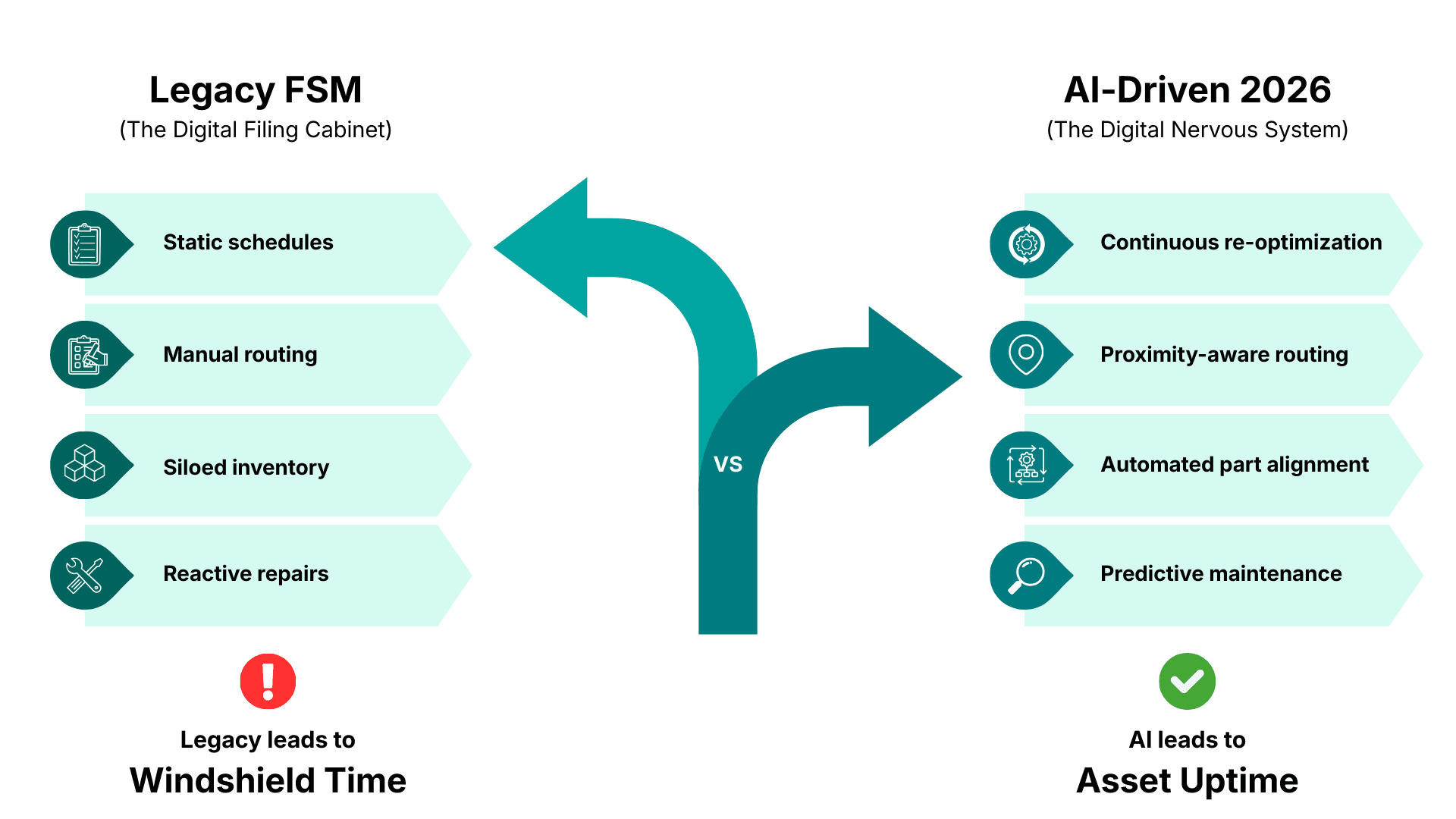

For decades, organizations relied on basic field service management software to keep records of what happened in the field. These systems were digital filing cabinets. They told you who went where and what parts they used, but they offered very little help in deciding who should go where next. In 2026, the industry has moved beyond record-keeping into the era of predictive execution. This blog explores how intelligent dispatch and route optimization are redefining uptime and why basic FSM is no longer enough to protect your margins.

The Limitation of Static Scheduling in a Dynamic World

Traditional FSM systems rely on static schedules. A supervisor looks at a list of pending jobs, a list of available technicians, and a map. They make the best guess possible, often hours or even days in advance. However, the industrial field is not static. A rig goes down unexpectedly in the Permian Basin. A flash flood closes a critical access road in a mining district. A technician with a specific certification gets delayed at a previous site due to an unforeseen complication.

In a legacy environment, these changes trigger a domino effect of inefficiency. The supervisor must manually call technicians, shuffle paper tickets, and try to re-route crews on the fly. This manual process is slow, prone to error, and results in massive amounts of "windshield time" where technicians are sitting in trucks instead of fixing assets.

Furthermore, basic FSM tools operate in silos. They do not know if the truck actually has the required components for the new job because the spare parts management system is disconnected from the scheduling tool. This lead to the dreaded "second trip," where a technician arrives at a remote site only to realize they lack the necessary tools or parts to complete the repair.

The 2026 Standard: Intelligent Dispatch

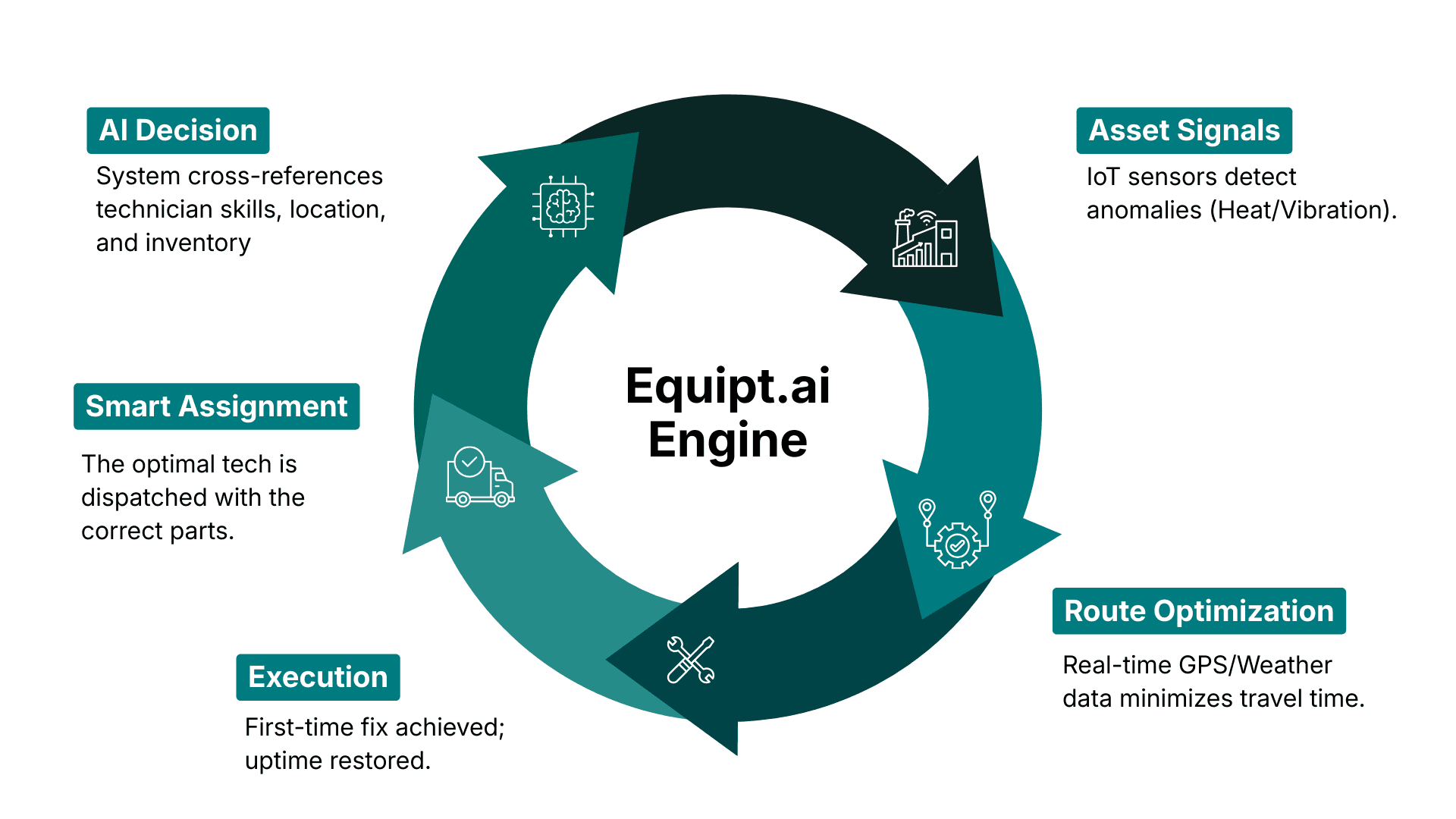

Intelligent dispatch is the heart of the Equipt.ai "System of Reality." Unlike basic scheduling, which is reactive, intelligent dispatch is proactive and continuous. It does not just look at who is available; it looks at a multi-dimensional matrix of data points to make the optimal decision in milliseconds.

1. Asset Condition Integration

Through advanced oil and gas asset management software, Equipt.ai monitors the real-time health of your fleet. If an IoT sensor detects a heat spike in a turbine or a vibration anomaly in a frac pump, the system doesn't just send an alert. It automatically creates a high-priority work order and begins looking for the best technician to intercept the failure before it occurs.

2. Skill-Based Logic

Not every technician is qualified for every job. Intelligent dispatch maintains a live database of certifications, experience levels, and even safety performance. The system ensures that high-complexity tasks are only assigned to senior leads, while routine maintenance is handled by juniors, maximizing your total workforce utility without risking compliance or safety.

3. Real-Time Resource Alignment

Before a job is dispatched, the AI verifies that the specific parts needed for the fix are either in the technician’s van or available at the nearest warehouse. By unifying field execution with equipment rental management software and inventory data, Equipt.ai eliminates the "parts gap" that plagues traditional operations.

Moving Beyond Simple Maps: AI Route Optimization

If intelligent dispatch is about "who" and "what," route optimization is about the "how" and "when." In 2026, route optimization is far more than just finding the shortest path between point A and point B.

Dynamic Re-Routing

In the energy sector, conditions change by the minute. Equipt.ai’s oil and gas software infrastructure ingests external data feeds, including weather patterns, traffic congestion, and road closures. If a road becomes impassable, the AI recalculates the routes for the entire fleet simultaneously. It might even swap jobs between two different technicians who are currently in transit to minimize the total drive time for the organization.

Proximity-Based Efficiency

By leveraging technician scheduling that is aware of GPS coordinates in real-time, the system can identify "incidental maintenance" opportunities. If a technician is finishing a job and there is a low-priority inspection required at a neighboring pad only five miles away, the system can append that task to their route. This prevents a separate truck roll the following week, significantly reducing fuel costs and vehicle wear and tear.

Carbon Footprint and Operational Cost Reduction

Efficiency is now tied to sustainability. By reducing unnecessary mileage through intelligent routing, companies are seeing a 15 to 20 percent reduction in carbon emissions from their field fleets. In 2026, this data is often required for regulatory reporting and ESG compliance, making AI-driven routing a financial and legal necessity.

The "System of Reality" vs. The "System of Record"

The fundamental difference between Equipt.ai and basic FSM providers is the transition from a "System of Record" to a "System of Reality."

A system of record tells you that a job was completed yesterday. It is retrospective. It is useful for accounting, but it does nothing for the crews currently standing on a wellhead.

A System of Reality, powered by Equipt.ai, tells you what is happening right now and what will happen in the next four hours. It bridges the gap between the back office and the frontline. When a supervisor looks at their dashboard, they aren't just seeing a list of names; they are seeing a living, breathing orchestration of resources. They see the flow of parts, the movement of crews, and the health of assets in one unified view.

Real-World Impact: The ROI of Intelligence

When companies transition from basic FSM to intelligent dispatch and route optimization, the results are immediate and measurable.

Increase in First-Time Fix Rates: By ensuring the right tech with the right part arrives at the right time, companies are seeing first-time fix rates climb above 90 percent.

Reduction in DSO (Days Sales Outstanding): Because the data is captured accurately at the moment of completion, the billing cycle starts instantly. As we have discussed in our guides on upstream billing, this can turn weeks of waiting into minutes of automation.

Lower Operational Overhead: Automation allows dispatchers to manage three times the number of technicians compared to manual methods. This allows organizations to scale their operations without ballooning their administrative costs.

Improved Asset Uptime: Predictive dispatching catches failures before they lead to unplanned downtime, which is the single most expensive event in any industrial operation.

Why 2026 Demands a New Approach

The complexity of modern industrial work has outpaced the capability of human-managed spreadsheets. Between shifting global demand, stricter environmental regulations, and a tightening labor market for skilled technicians, "good enough" is no longer a viable strategy.

Equipt.ai was built specifically for these high-stakes environments. Our platform does not just provide a mobile app for your techs; it provides a digital nervous system for your entire operation. We understand that in the oilfield, the mine, or the rental yard, every minute of delay is a minute of lost revenue.

Conclusion: Don't Get Left Behind

The year 2026 marks the end of the era for static, basic FSM software. The industry leaders of tomorrow are already implementing the intelligent systems that turn chaos into orchestrated efficiency. By adopting intelligent dispatch and route optimization, you are not just upgrading your software; you are future-proofing your business.

Equipt.ai is the only platform designed to provide a true System of Reality for the world's most demanding industries. Whether you are managing complex requirements or trying to streamline a massive rental fleet, our AI is ready to help you win.

Ready to see the future of field service in action? Stop fighting your legacy systems and start empowering your crews. Book a strategy session with Equipt.ai today and discover how 60 seconds of AI can replace 60 minutes of manual chaos.