Helicopters, Harsh Shifts, High Stakes: How Offshore Teams Can Stay Safe

From grueling shifts to risky chopper rides, offshore crews face extreme conditions—here’s how the right tools and practices keep them safe.

- Offshore Teams

Offshore operations are among the toughest workplaces, where safety is not just about following compliance but a matter of survival. The risks are undeniable. In fact, in 2023, US offshore facilities reported 200+ worker injuries and 350+ lifting accidents, many during routine tasks that went wrong.

An offshore platform is a place where every minute counts, and every task involves risks. For business owners, this environment causes constant worry. It leads to real costs, such as downtime, insurance claims, compliance fines, and most importantly, the safety of skilled workers. The challenge is not just managing work but also dealing with the many unpredictable dangers involved. That’s why relying on old methods like paper checklists is no longer a way to handle it all.

We have already entered a new era of digital safety, where technology effectively mitigates offshore risks before they occur. In this blog, we will explore the top offshore safety concerns, discuss how technology can help mitigate these risks, and provide additional insights. Let us dive in.

Why Traditional Offshore Safety Measures Aren’t Enough?

Oil and gas extraction remains one of the most dangerous industries in the world. The fatality rate for workers is seven times higher than for all other U.S. industries, and transportation incidents like helicopter crashes are among the leading causes. Even with safety rules, traditional methods are not enough to protect workers in challenging environments. Here are the primary reasons.

1. Paper Checklists and Manual Inspections Are Risky

When inspections use paper checklists or manual reporting, mistakes can occur. In offshore conditions, even a small mistake can lead to serious risks.

2. Lack of Visibility for Onshore Management

Managers sitting onshore usually have limited visibility of what is happening in the field. Without real-time updates, they cannot respond quickly to emerging risks.

3. Delays in Data Sharing

Slow or incomplete data flow means that risks are not addressed right away. By the time decision-makers receive the information, it may be too late to prevent an incident.

4. Gaps in Equipment and Gear Tracking

Workers often lack the proper tools or protective gear when they need them. This shortage of gear puts both technicians and operations at risk.

5. No Real-Time Alerts

Traditional systems do not provide live updates or alerts when conditions change, or equipment fails. This puts workers at risk of unexpected dangers.

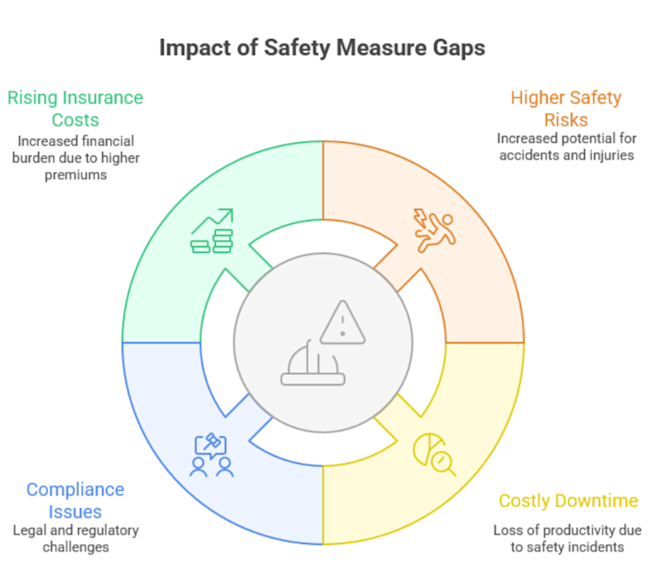

So, what does this mean for business leaders? For companies, these gaps have a direct impact.

Therefore, relying on outdated safety measures is no longer a sustainable approach. Offshore teams require modern, digital safety solutions like AI-powered oil and gas data management software that provide real-time visibility, quick responses, and proactive protection.

AI-Driven Cost Optimization Tactics for Oilfield Equipment and Services

How IoT and AI Improve Offshore Safety Management?

Offshore environments require constant attention, and technology plays a critical role in this. Oil and Gas Industrial Internet of Things (IIoT) sensors are changing the energy industry, but why are they so critical? IIoT, AI, and real-time monitoring tools enable companies to move from reactive safety practices to proactive risk prevention.

And this certainly doesn't end here. There is a lot more to it. Below are some ways these technologies are enhancing offshore safety management.

1. Real-Time Data for Real-Time Decisions

IIoT sensors continuously monitor equipment and environmental conditions, like pressure, temperature, and gas leaks. So, instead of waiting for regular inspections, data is sent immediately to control centers. This allows teams to identify potential issues and act before they become safety risks.

2. Smart Recommendations

AI analyzes sensor data to predict equipment failures and identify patterns that humans might miss. For example, if a drilling pump's vibration levels are too high, the AI system can suggest maintenance before the pump breaks down. This helps prevent accidents due to equipment failure and reduces the chances of costly downtime.

3. Intelligent Tools for Technicians

Wearable IoT devices, like smart helmets, safety vests, and wristbands, track worker health and exposure levels. These devices can sense fatigue, gas exposure, or heat stress in real time and alert supervisors right away. This ensures workers receive help before a situation becomes dangerous.

4. Seamless & Safe Workflows

IoT platforms integrate data from equipment, environment sensors, and wearable devices into a single system. This unified view allows managers to coordinate workflows better, automate safety checks, and ensure compliance. As a result, there are fewer delays, safer task execution, and faster emergency responses.

The oil and gas sensor market is expected to grow to $2.4 billion by 2030. This shows that the industry is increasingly adopting digital safety technologies.

Working With vs. Without Smart Safety Systems

Offshore operations are high-risk, and safety depends on having the right systems in place. Traditional manual approaches often leave gaps, while modern IIoT and AI-based solutions provide real-time visibility and proactive protection. The table below aptly differentiates offshore safety management using traditional and intelligent systems.

Aspect | Traditional / Manual Systems | IIoT & AI-Based Systems |

Safety Checks | Paper checklists are prone to errors and inconsistencies. | Automated checks with digital logs, ensuring accuracy and accountability. |

Incident Reporting | Often delayed since issues are recorded after escalation. | Real-time alerts and instant reporting to onshore and offshore teams. |

Visibility | Limited. Managers rely on verbal updates or delayed reports. | Live dashboards give onshore management real-time insight into worker and equipment status. |

Equipment Readiness | No systematic tracking; risk of missing tools or protective gear during shifts. | IoT sensors track gear availability and condition, ensuring workers are always equipped. |

Maintenance | Reactive as problems are fixed only after failures occur, causing downtime. | Predictive. AI forecasts failures and schedules maintenance before breakdowns. |

Worker Safety | Dependent on manual compliance and human oversight. | Enhanced automated workflows, guided safety steps, and data-driven recommendations. |

Operational Impact | Higher downtime, greater compliance risks, increased insurance, and operational costs. | Reduced downtime, improved compliance, lower costs, and better overall efficiency. |

Equipt.ai’s Role in Enabling Safer Offshore Teams

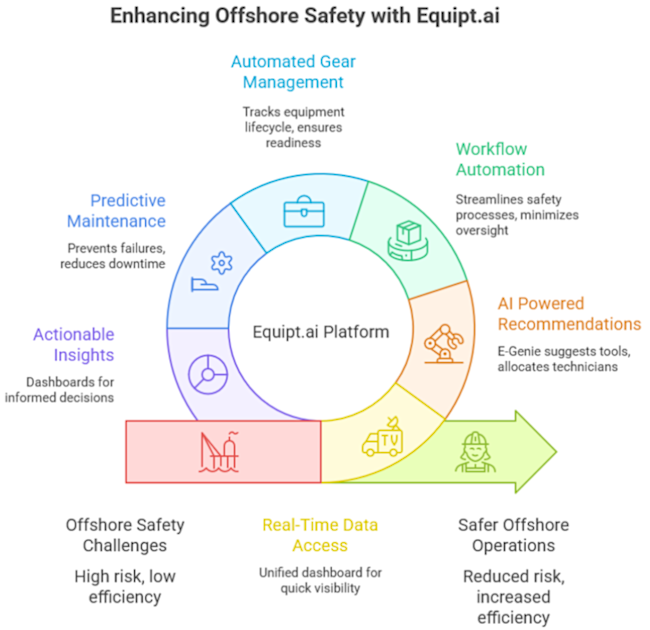

Equipt.ai offers smart solutions for offshore safety, equipment, and teams. It helps offshore teams by combining IIoT, AI, and automation into one platform that puts safety and efficiency first. So, instead of waiting for updates or using scattered checklists, managers and field technicians can access real-time data, automated workflows, and predictive insights. This helps prevent issues before they lead to accidents. Here is how we help:

Real-Time Data Access

Real-time visibility gives managers immediate access to equipment and crew status. Our unified dashboard collects data from job sites, maintenance logs, vendors, and equipment, providing quick visibility and control. So, no more juggling spreadsheets or waiting on delayed reports.

AI Powered Recommendations for Safety and Efficiency

AI-powered recommendations ensure tasks are planned and executed with precision. Using AI-assisted intelligence named E-Genie, our offshore safety solution suggests the right tools, allocates technicians by skill, and plans jobs smartly. This reduces errors, rework, and risk.

Workflow Automation to Reduce Risk Exposure

Automated workflows make sure that all safety steps are followed correctly. Our solution streamlines these processes to minimize oversight and protect workers.

Automated Gear and Tool Management

Our platform tracks the lifecycle of equipment and inventory management, including inspections, warranties, and readiness. This ensures that workers always have the necessary gear, and managers can manage stock proactively. For companies relying on shared assets, integrating robust equipment rental management software can further streamline tracking, allocation, and compliance, ensuring offshore teams are never left without critical tools.

Predictive Maintenance and Compliance

Our AI powered & IoT predictive maintenance helps prevent equipment failures, reduce downtime, and avoid costly accidents. We use data and alerts to schedule repairs before problems occur, ensuring safety and compliance.

Actionable Insights

Dashboards and reports provide the leadership with important data to make quick and informed decisions. Real-time dashboards and tailored reports help management optimize costs and maintain compliance.

For business leaders, our intelligent solutions address real operational challenges. They reduce risk, ensure compliance, enhance uptime, and most importantly, protect workers.

Companies using IIoT and AI have reported, incident response times cut by over 60% and operating costs reduced by 12–20%.

Investing in Offshore Safety Is Investing in Success

Offshore work is high-risk, and outdated methods are a liability. Every delay, missed check, or equipment failure can cost millions and put lives at risk.

Digital safety platforms change this equation. By combining real-time visibility, predictive maintenance, and automated workflows, they cut downtime, strengthen compliance, and build trust across teams.

For business leaders, the takeaway is simple: safety is an investment in resilience, efficiency, and long-term success. Get the technology-powered solution to gain a competitive edge and safety for your offshore staff.

People Also Ask / FAQs

Why is offshore safety so important?

Offshore operations involve high-risk tasks in extreme environments. Ensuring safety prevents accidents, protects workers, and reduces costly downtime and compliance risks.

How to improve offshore team safety?

Offshore team safety can be improved by moving beyond paper checklists and adopting digital safety tools. IoT sensors provide real-time visibility into equipment and worker conditions, AI predicts failures before they happen, and automated workflows ensure safety steps are never missed. Together, these technologies reduce risks, cut downtime, and protect workers while improving operational efficiency.

What are the limitations of traditional offshore safety methods?

Paper checklists, manual inspections, and delayed reporting often miss risks, create visibility gaps, and result in slower response times during emergencies.

How can IoT improve offshore team safety?

IoT sensors provide real-time data on equipment, environment, and worker health, enabling managers to detect risks early and take action before accidents occur.

What role does AI play in offshore safety?

AI predicts equipment failures, recommends safer workflows, and reduces errors. This ensures operations run smoothly while minimizing risks to workers.

How do digital safety platforms benefit business leaders?

They reduce downtime, cut operational costs, improve compliance, and build trust by ensuring offshore teams work in safer & smarter conditions.

Is investing in offshore safety technology expensive?

While it requires upfront investment, digital safety tools reduce long-term costs by preventing accidents, lowering insurance claims, and minimizing unplanned downtime.