Spare Parts Management with AI: Turning Inventory Data into Uptime Intelligence

Move spare parts management beyond spreadsheets with AI that improves uptime, planning, and cost control.

- Inventory Management

Quick Summary

AI is transforming spare parts management from guesswork to precision. With predictive insights, real-time visibility, and smarter stocking, businesses can reduce downtime, lower costs, and achieve true uptime intelligence.

Introduction

Downtime hurts more than most business leaders admit. In fact, a recent industry reports show that unexpected equipment stoppages can cost companies over $260,000 an hour, and in sectors like automotive or energy, that number can shoot up to $2 million or more per hour.

Many organizations face significant financial challenges because they manage spare parts using outdated spreadsheets, scattered data, and considerable guesswork. Spare parts planning is often viewed as a minor function, but it actually has a significant impact on the frequency of operations running smoothly.

Companies often make mistakes in this area. They either stock too many parts “just in case” or find themselves out of stock at critical times. Both situations waste money and lead teams to react under pressure.

Fortunately, things are improving. Artificial intelligence is providing companies with a smarter way to manage spare parts by using real data, patterns, and predictions. Instead of waiting for downtime to happen, leaders can now prepare in advance. Platforms like Equipt.ai help businesses transform basic inventory data into valuable insights about uptime, enabling faster and clearer maintenance decisions. In this blog, we will explain how AI changes spare parts management from a cost burden into a strategic advantage.

Why Spare Parts Management Remains a Major Blind Spot

You’d think with so much riding on spare parts, companies would have it down, but in reality, this is one of the biggest hidden leaks in many operations.

1. The Over-and-Under Stocking Problem

Maintenance and operations leaders often face a tough challenge. If they order too many parts “just in case,” they tie up a lot of cash. If they order too few, a broken machine can stop production. It’s a constant balancing act. Many organizations tend to overstock items to avoid costly downtime.

2. Stockouts Create Real Risk

When a critical spare part is missing, it causes serious problems. Stockouts can delay repairs and even halt production completely. This impacts revenue, damages customer trust, and may even create safety issues in some industries.

3. Siloed Inventory Data Across Plants

Many companies operate in separate units, with each plant or department using its own inventory system. This means they often don’t share information. As a result, it’s difficult to locate parts, which makes it challenging to move spare parts around, eliminate duplicates, or even identify what items are truly essential.

4. No Real-Time Visibility

Without real-time insights, planning for spare parts relies on old reports instead of current demand. Therefore, leaders make decisions based on outdated data, which can lead to a reactive approach to problems instead of proactive planning.

5. Inactive Stock Draining Capital

Many maintenance organizations find that 50–60% of their maintenance, repair, and operations (MRO) inventory is not being used. This dead stock often sits in storage, untouched.

Over time, maintaining this “just-in-case” inventory can lead to high expenses. Storage fees, write-offs, and tied-up working capital can add up, creating a substantial financial strain. AI offers predictability and accuracy in this area. Instead of relying on intuition or incomplete data to manage spare parts, AI provides:

With AI tools for forecasting and managing inventory, leaders can view their spare parts as a valuable resource for improving uptime and performance, rather than just a necessary burden.

As AI and data tools become more prevalent, spare parts strategies are evolving to become more connected, proactive and predictive. The global market for predictive maintenance, which enables smarter spare parts planning, is expected to reach $60.13 billion by 2030. This growth represents an annual rate of about 29.5%.

Your Spare Parts Strategy Is Holding You Back

Modernize it with AI and gain the uptime advantage your competitors alrady use.

What AI Really Brings to Spare Parts Management?

Spare parts teams have long struggled to strike a balance between having “too much” and “not enough.” AI finally brings that balance within reach. In fact, AI-led inventory optimization has been shown to reduce overall inventory costs by 20–40%, without compromising uptime.

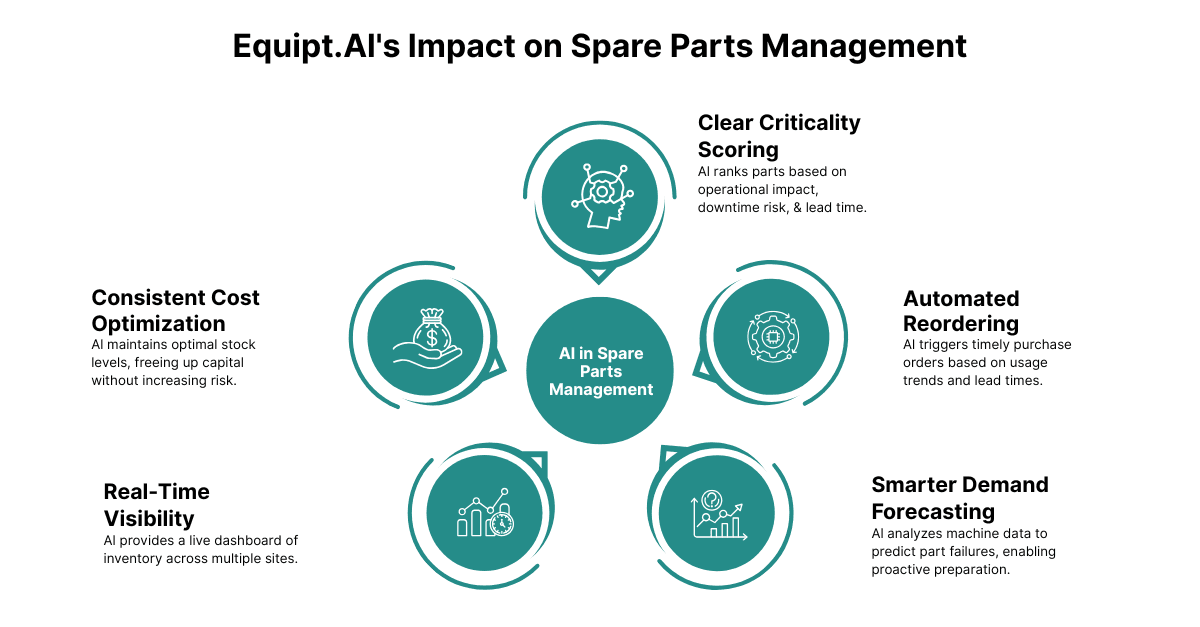

Here’s how modern AI platforms, like Equipt.ai, make this transformation practical and reliable:

1. Smarter Demand Forecasting

Instead of relying on past consumption or gut instinct, AI studies patterns in machine behavior, usage cycles, and breakdown history. Equipt.ai does this remarkably well by turning raw maintenance logs and sensor data into predictions you can trust.

2. Clear Criticality Scoring

One of the biggest challenges for leaders is knowing which components truly matter. Equipt.ai’s models automatically rank parts based on their operational impact, downtime risk, and replacement lead time.

3. Automated and Timely Reordering

With AI monitoring usage trends and supplier lead times, reordering becomes proactive rather than frantic. Equipt.ai can recommend and even automatically initiate purchase orders at optimal moments. This helps reduce emergency purchases and prevents the common panic of thinking you have one more piece left.

4. Real-Time Visibility Across All Plants

Inventory scattered across multiple sites is one of the biggest blind spots in spare parts planning. AI fixes that. Equipt.ai brings all your spares data together into one live dashboard, so you always know what’s available, what’s moving, and where the gaps are.

5. Consistent Cost Optimization

By helping you maintain the right level of stock, AI frees up working capital without increasing risk. Equipt’s optimization engine continuously adjusts recommendations as real-world data changes, ensuring you’re always running lean but protected.

Your Competitors Are Already Using AI. Are You?

Stay ahead with smarter forecasting and real-time parts visbility.

Turning Inventory Data into Uptime Intelligence: How It Actually Works

Many companies already have the data they need, but it's often scattered across different locations. AI helps turn this messy data into real uptime intelligence, and platforms like Equipt.ai make the entire process smoother and more practical. Here's how the transformation actually happens:

1. Data Collection

The process begins by gathering data from your current systems, like ERP, CMMS, sensors, maintenance records, supplier histories, and warehouse databases. Our platform integrates with these systems, allowing leaders to gain a comprehensive and clear view of their spare parts environment.

2. Data Cleaning & Normalization

Spare parts data often contains duplicates, inconsistent names, and outdated items. Our AI solution cleans up this data by standardizing part names, removing duplicates, flagging obsolete items, and organizing everything into a clear and usable format.

3. Predictive Modeling

Once the data is clean, AI begins identifying trends like seasonal usage, repetitive failure patterns, machine behavior, supplier performance, and more. Our predictive models use all this to forecast which parts will be needed, and when, giving operations teams a head start instead of a surprise.

4. Inventory Optimization

Here's how you can use uptime intelligence effectively. The AI engine suggests:

The best points to reorder supplies

The right levels of safety stock

Stocking guidelines for each plant

How to balance critical and non-critical spare parts

Our platform continually updates these suggestions based on actual usage to help leaders meet demand without holding too much inventory.

5. Real-Time Alerts & Decision Support

Users receive real-time alerts about potential stockouts, unusual usage, high-risk parts, supplier delays, and predicted failures, instead of having to sift through reports. Our E-genie agent provides proactive recommendations, allowing planners, maintenance leads, and supply chain managers to respond quickly.

Your Inventory Is Costing You More Than You Think

See how AI turns hidden inefficiencies into measurable uptime gains.

Key Benefits That Matter to Business Leaders

AI streamlines spare parts management, making it clearer, faster, and more reliable. Here’s what it actually means for your operations:

Reduce Downtime: Identify problems early to keep machines running and cut breakdowns by 30–50%.

Lower Inventory Costs: Prevent overstocking and reduce extra inventory by 20–40%.

Enhance Maintenance Planning: Proactively identify issues before they occur.

Simplify Supplier Coordination: Get better lead times and avoid last-minute rushes for parts.

Identify Critical Parts: Easily see which parts are essential for smooth operations.

Real-World Use Cases of AI in Spare Parts Management

AI is changing how industries with heavy equipment manage their spare parts, and the benefits are clear.

In manufacturing, AI predicts when parts like belts, bearings, or gears will fail. This helps teams stock only what they need. In the oil and gas sector AI tracks crucial spare parts across remote rigs, lowering the chance of unexpected shutdowns. The automotive and heavy machinery industries utilize AI to forecast demand for key components, thereby reducing delays and unnecessary purchasing. Utilities also use AI to manage spare parts for turbines, transformers, and other power assets.

One notable example is a global manufacturer that reduced its annual inventory costs by 28% by switching from spreadsheets to AI-based planning. This change highlights how platforms like Equipt.ai can turn complex data into clear and reliable maintenance choices.

The Future of Uptime Runs on Spare Parts Intelligence

Downtime is no longer something leaders have to put up with. With AI, managing spare parts moves from guesswork to insight. This change turns a cost burden into an advantage for keeping things running smoothly. Companies using data-driven forecasting, real-time visibility, and smarter stocking are experiencing fewer breakdowns, lower inventory costs, and quicker decision-making.

As more companies adopt AI for maintenance, tools like Equipt.ai provide the information they need to remain strong and competitive. If you want to achieve higher uptime and leaner operations, the next step is clear: start using your inventory data as a strategic asset, not as a hidden problem.

Marketing strategist at Equipt.ai, specializing in B2B SaaS growth for the oil and gas industry. He combines data-driven campaigns, targeted outreach, and thought leadership content to connect field operations and decision-makers with innovative asset management solutions.