Case Study

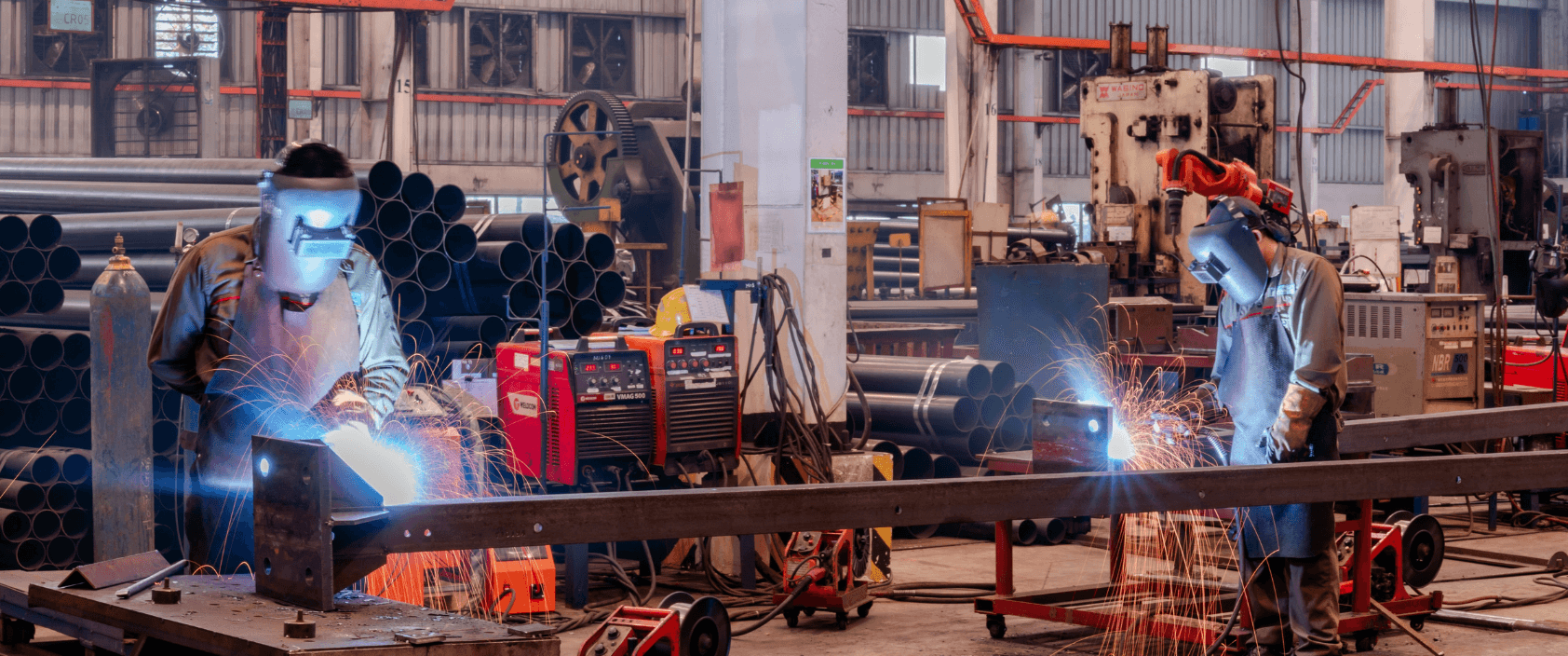

EPC & Fabrication

Industry

EPC & Fabrication

Overview

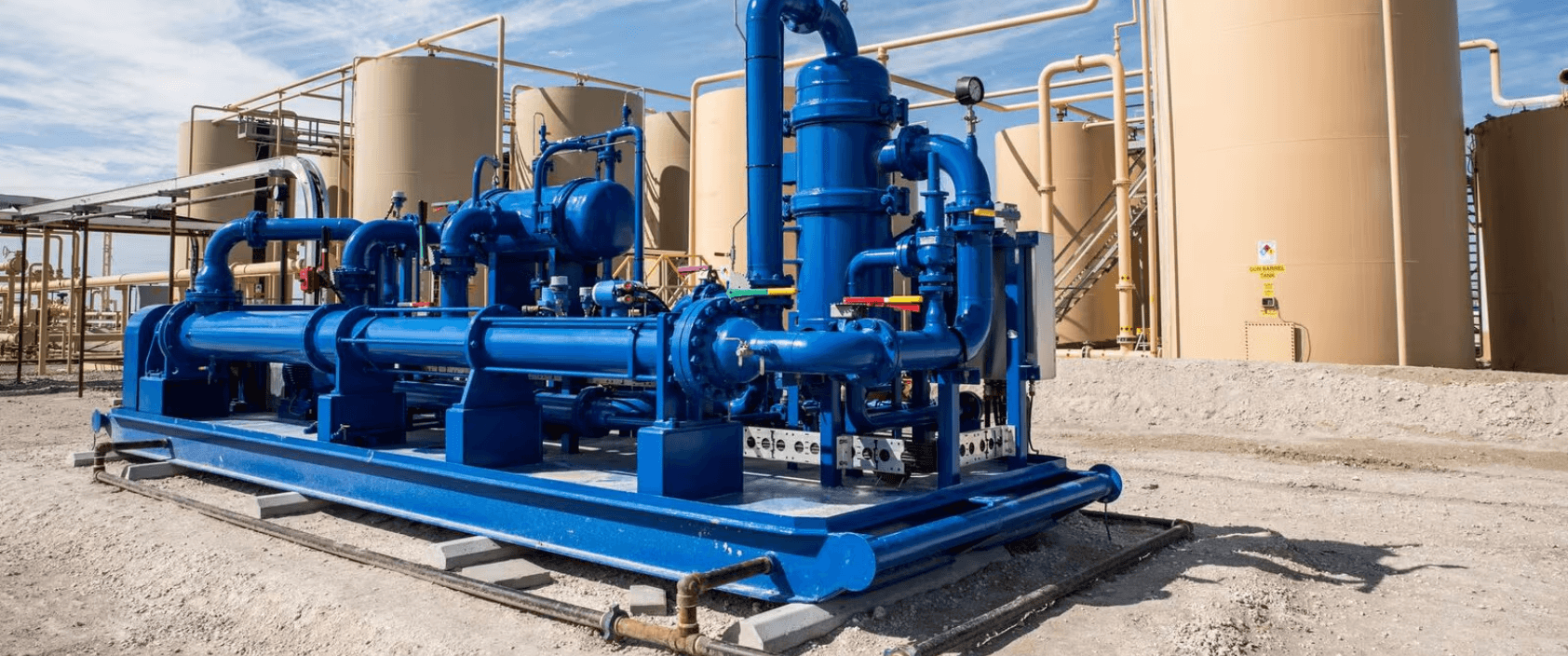

EPC fabrication firm digitized up to 8,000 monthly orders, eliminating paper workflows and manual inventory tracking across massive global pipe and module fabrication operations.

Protect your margins with accurate field data from job to invoice

Challenges Faced

Disconnected work order management Work orders, drawings, and material movements were managed on paper or in disconnected systems.

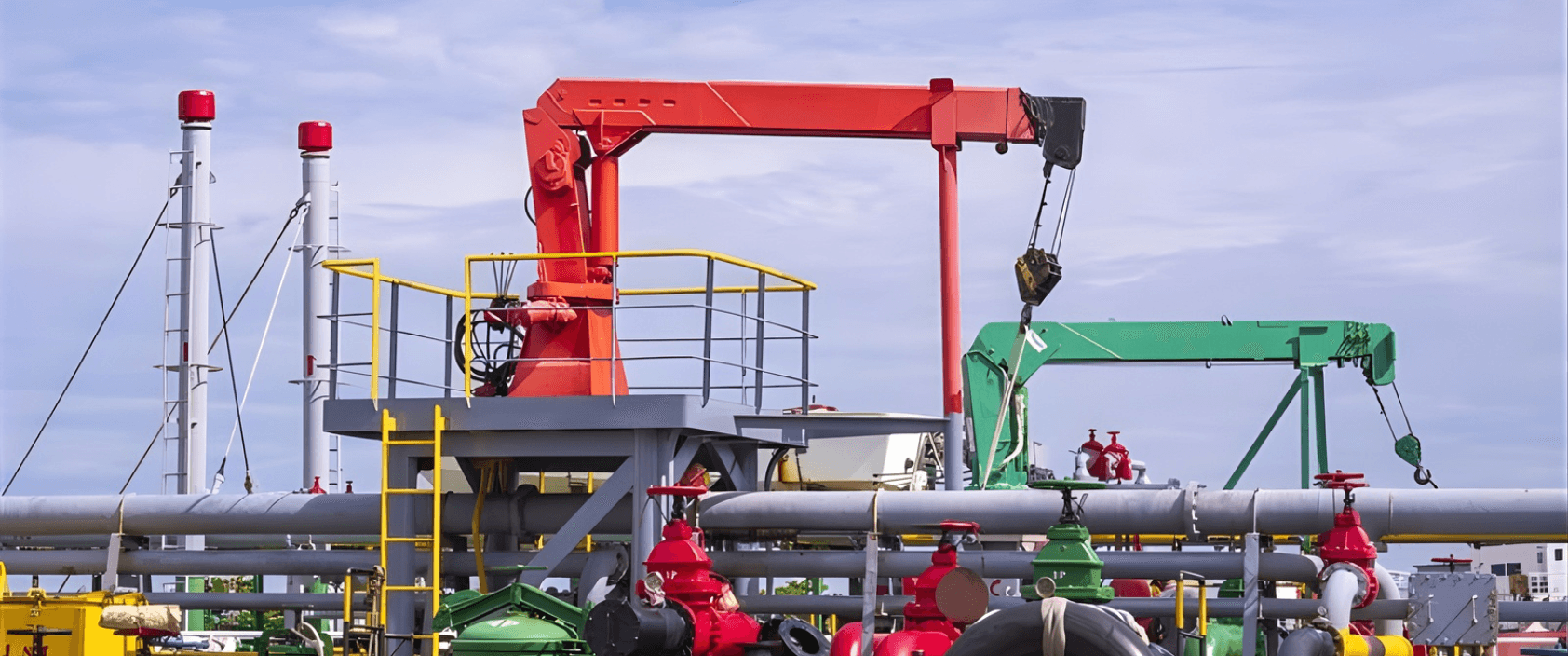

Limited supervisor visibility Supervisors had limited visibility into live workloads, technician assignments, and material status for thousands of active jobs.

Slow mass work order creation Mass work order creation was slow and error-prone. Manual inventory tracking led to delays and rework.

Solution

Modernizing EPC Production with Equipt.ai

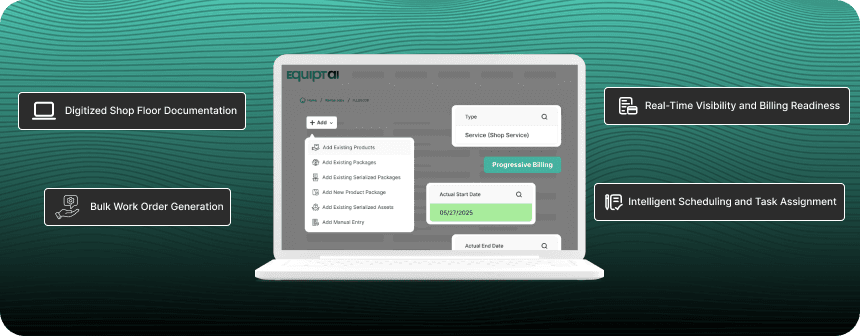

Digitized shop floor documentation: All production activities and traveler documents are recorded digitally, eliminating paper and reducing lost or incomplete records.

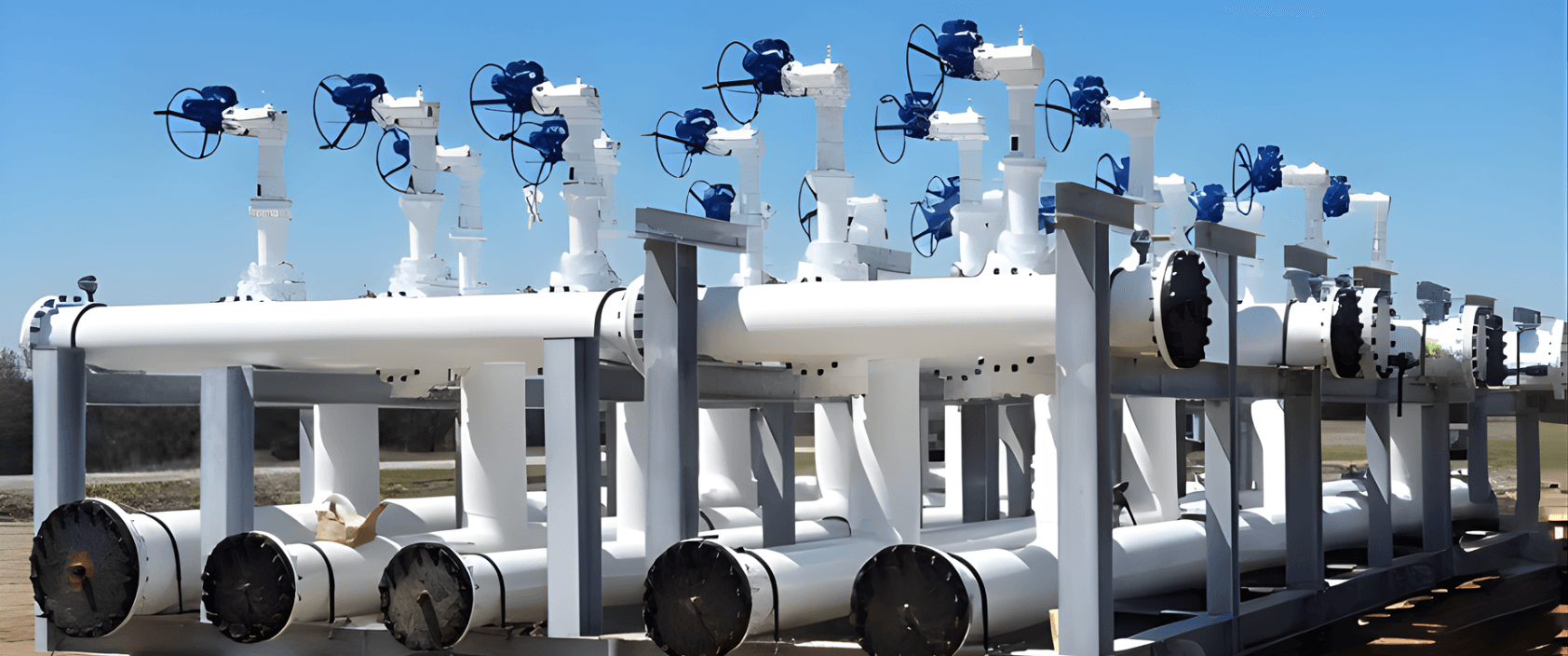

Bulk drawing uploads and mass work order generation: Teams can upload drawing packages and generate 2,500+ work orders with a single click, significantly reducing setup time.

Intelligent scheduling and task assignment: Technicians see intuitive task views for prioritization, while supervisors optimize resource scheduling across lines and shifts.

Real-time visibility and billing readiness: Live dashboards show workloads and progress, enabling accurate billing and improved cash flow.

Results

Increase in operational efficiency through digitized production management

15–20% improvement in technician and production line utilization

Faster, more accurate billing from real-time visibility

Reduced bottlenecks in scheduling and approvals

Testimonial

Equipt.ai transformed our pipe shops from paper-heavy and reactive to fully digital and predictable. Supervisors now have live visibility into workloads, materials, and technician capacity, with mass work orders created in minutes instead of days

Pipe Fabrication Operations Manager

Related Success Stories

Simplify Complex Operations and Unify Everything On Equipt.ai

No IT overhaul required

Copyright © 2025 - ALL RIGHTS RESERVED