Case Study

Integrated Oilfield Services Provider & OEM

Industry

Integrated Oilfield Services Provider & OEM

Overview

An integrated oilfield services provider and OEM modernized field ticketing, fabrication, and equipment planning with Equipt.ai's unified digital platform.

Protect your margins with accurate field data from job to invoice

Challenges Faced

Dispatching and Job Scheduling Chaos: Field crews and dispatchers relied on phone calls, emails, and spreadsheets to schedule jobs, request inventory, and route equipment, which led to frequent errors and delays.

Production and Work Visibility Gaps: Fabrication work orders, assemblies, and material movements were managed in silos, leaving supervisors with limited visibility into technician utilization, actual hours, and production status.

Approval and Compliance Bottlenecks: Approvals and quote‑to‑cash processes were fragmented, making compliance checks and audit trails time‑consuming, while inconsistent data across systems made it difficult to analyze performance, control inventory, and track delivery against customer commitments.

Solution

Modernizing Operations with Equipt.ai

Unified field scheduling and routing Crews and jobs are scheduled in a single system using skills, hours, and proximity, while optimized routing improves daily job counts and reduces manual coordination.

Digital quote‑to‑invoice workflows Requests, approvals, changes, and invoicing run through one workflow with embedded compliance checks and instant digital field ticketing, reducing billing errors and admin delays.

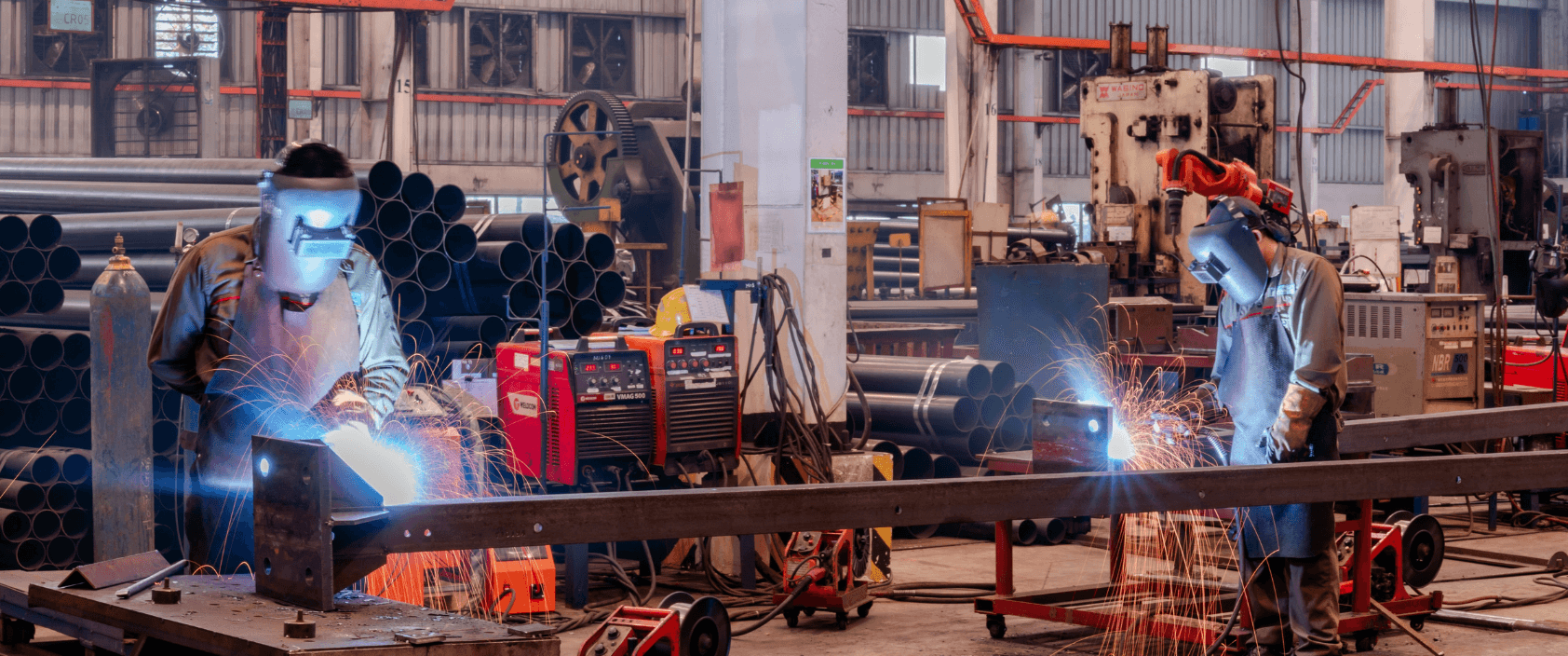

Automated Drawing Parsing Fabrication travelers and work orders are fully digital, with assembly and BOM data extracted from drawings to eliminate manual entry and improve data accuracy.

Technician utilization and time accuracy Centralized scheduling and digital time capture replace estimates with actual hours, improving cost insight, utilization, and production planning.

Inventory and materials control Parts requested on the field and shop material movements are approved and tracked in-system, delivering end‑to‑end traceability and tighter control over inventory.

Performance visibility for service and manufacturing Interactive dashboards surface real-time KPIs for field jobs and fabrication lines, helping leaders identify bottlenecks, improve throughput, and ensure on-time delivery.

Results

Complete digitization of field service workflows and fabrication travelers.

Crew and technician utilization improved by 12–15% through accurate, real-time scheduling.

Production order setup times accelerated by 36%, from submission to execution.

Improved data accuracy across BOMs, work orders, and inventory.

Faster, more accurate invoicing with full compliance and audit trails.

Testimonial

Equipt.ai brought our field service and manufacturing teams onto the same digital playbook... We've cut manual admin work, improved utilization, and can prove compliance on every job.

Vice President Services and Operations

Related Success Stories

Simplify Complex Operations and Unify Everything On Equipt.ai

No IT overhaul required

Copyright © 2025 - ALL RIGHTS RESERVED