Case Study

Pressure Control Equipment & Service Provider

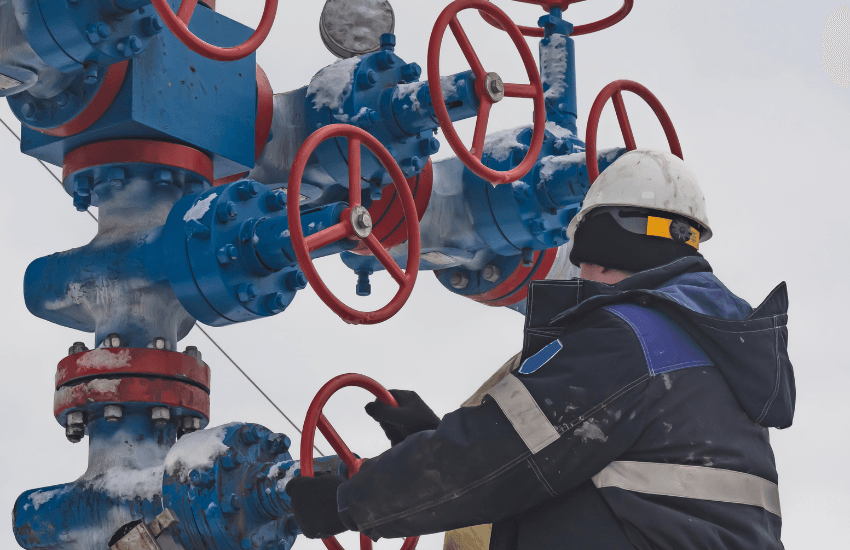

Industry

Pressure Control Equipment & Service Provider

Overview

Pressure control provider unified equipment tracking, job planning, and certification management across multiple basins with Equipt.ai's connected platform for planning, execution, maintenance, and compliance.

Protect your margins with accurate field data from job to invoice

Challenges Faced

Fragmented equipment tracking Equipment movements, inspections, and certifications were tracked in spreadsheets and on paper, creating blind spots and dispatch delays.

Manual program and list assembly Engineers and coordinators manually assembled job programs, equipment lists, and customer requirements from scattered files, while field and shop teams worked in separate tools, making it hard to prevent double‑bookings, underutilization, or idle assets across regions.

Slow, risky compliance reporting Compliance reporting and documentation were slow to compile and prone to error, increasing risk in pressure control and surface operations

Solution

Modernizing Pressure Control Operations with Equipt.ai

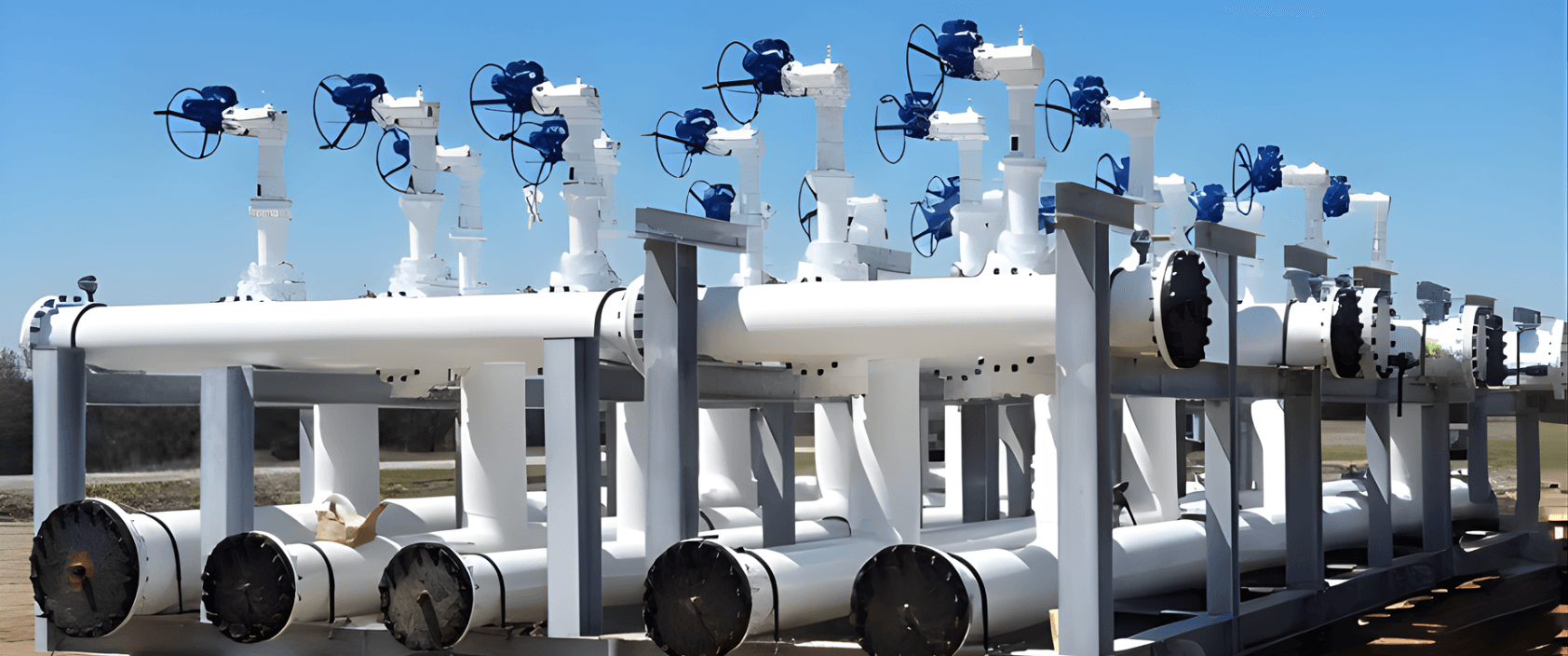

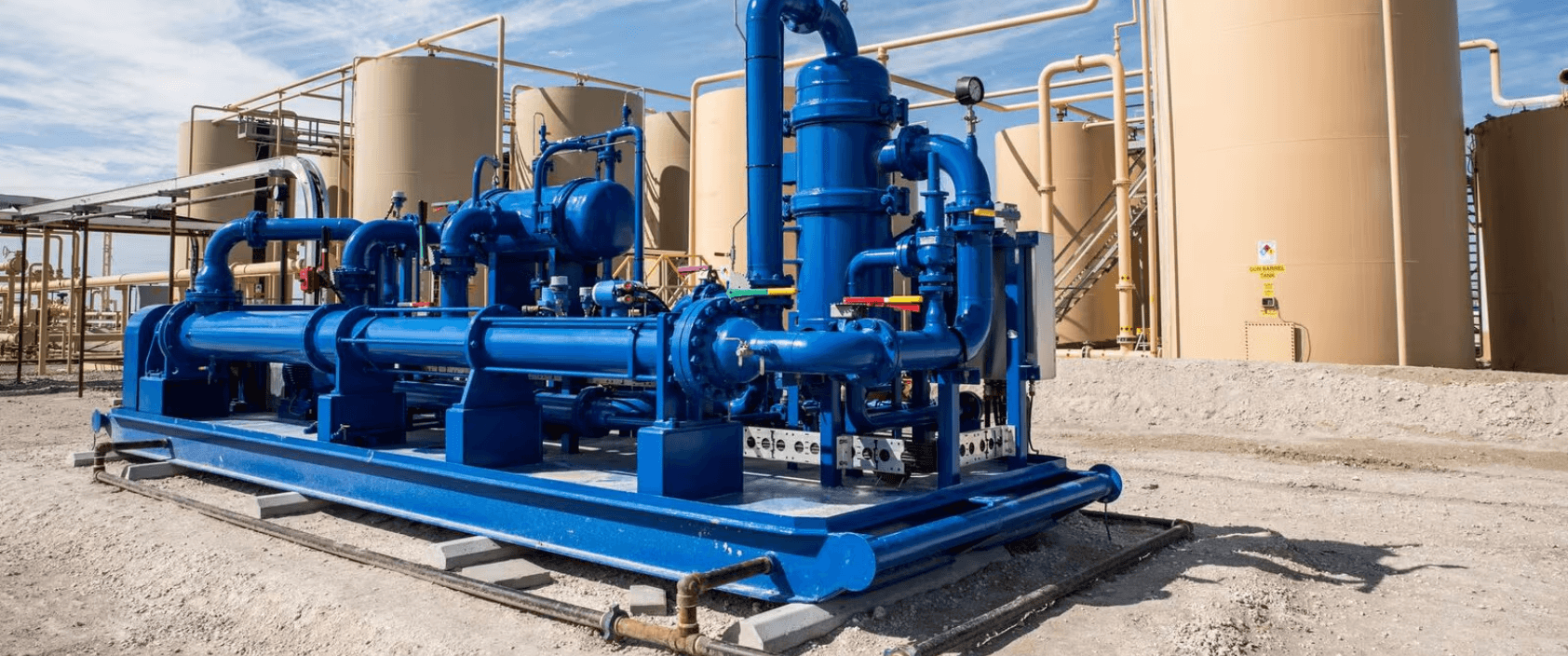

Unified asset tracking for pressure control fleets All frac stacks, valve and manifold assemblies, pressure control iron, and related equipment are tracked in one system with real-time location, condition, readiness, and certification status.

AI‑driven job design and planning Customer files and stage designs are imported once; the platform parses the data and builds job programs, equipment lists, and inventory plans automatically, reducing manual engineering effort.

Connected field service workflows Rig‑up/rig‑down, testing, torque, repairs, and site services are managed digitally with mobile-ready work orders, giving supervisors and coordinators a live view of job progress.

Proactive maintenance and compliance Maintenance schedules and certification renewals are driven by usage and condition data, with automated reminders and audit-ready histories that reduce unplanned downtime and compliance risk.

End‑to‑end commercial visibility From initial planning through execution and billing, job, asset, and inventory data flow through one ecosystem, cutting cycle times and eliminating reconciliation headaches between business units.

Profitability and cost control intelligence Technician hours, asset cost, and inventory usage are captured against each job, with cost books, technician types/competencies, and sublease costs managed in one place—enabling job, part, and technician-level profitability analysis.

Results

Manual data entry reduced by up to 85% and complex planning time significantly lowered.

18–24% reduction in equipment idle time and measurable decreases in unplanned downtime.

Faster response and higher job readiness from real-time asset and job visibility.

Stronger compliance through automated certification tracking and structured digital records.

Improved utilization and a connected ecosystem linking equipment, jobs, inventory, and field crews.

Testimonial

Equipt.ai's Rental Equipment Management portal went live so quickly. It's extremely intuitive, and our employees can already see higher efficiency and fewer headaches in daily operations.

President & CEO

Related Success Stories

Simplify Complex Operations and Unify Everything On Equipt.ai

No IT overhaul required

Copyright © 2025 - ALL RIGHTS RESERVED